References

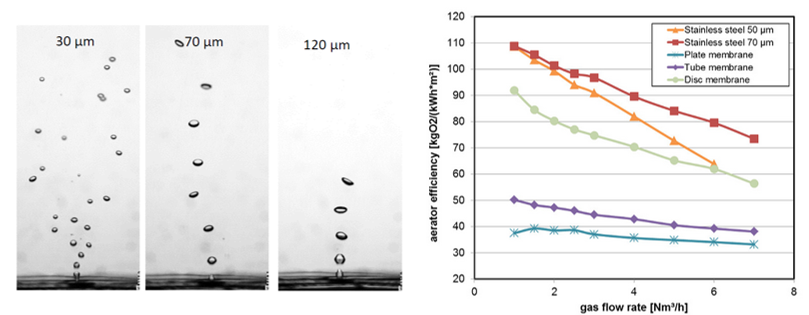

Microperforated spargers

The air injection required for biological wastewater treatment is normally carried out by using pressurized air diffusers with perforated flexible membranes that are mounted at the bottom of the activated sludge tanks. Due to the limitations related to the short residence time of the ascending air bubbles and the restricted contact area between the liquid and gaseous phases, the amount of oxygen that is actually transferred to the liquid phase and made readily available for microorganisms is much lower than the amount initially injected. For this reason, even modern diffusers achieve a relatively low standard oxygen transfer efficiency (SOTE) in the order of 40-60 % (Wang et al. 2010). The optimization of this process would result in significantly lower energy demand for biological wastewater treatment systems.

Novel technologies for energy efficient air injection have been thoroughly studied as part of a long-term collaboration project between the Institut für Wasser & Energie Bochum GmbH (IWEB) and the experts of CLEWATEC. Part of the results of this collaboration have been presented in the SEBAK project, which received the support of the Ministry for the Environment, Agriculture, Nature and Consumer Protection of North Rhine-Westphalia. Results of laboratory studies reveal that significantly smaller gas bubbles are generated by micro-perforated stainless steel plates compared to commercial rubber membrane spargers (Mohseni et al. 2017). This translates into significantly higher aeration efficiency compared to commercial rubber membrane spargers.

Literature

- Mohseni, E., Herrmann-Heber, R., Reinecke, S. F., Hampel, U., Bubble Generation by Solid Membrane Spargers for Activated Sludge Wastewater Treatment Application. Proceedings of 9th Eastern European Young Water Professionals Conference IWA YWP, 24.-27. May 2017, Budapest, Ungarn (2017).

- Wang, L. K., Shammas, N. K., Hung, Y.-T., Advanced biological treatment processes – Volume 9. Berlin (Germany): Springer Science & Business Media (2009).